For the Europe Day on May 9th, discover the European project PowderReg: Federating cross-border expertise to better understand the behavior of powder flows in industry.

How to characterize powders and granular media under different conditions? Actors from the Greater Region have joined their expertise to improve their knowledge and define the behavior laws that govern these powders.

Launched in 2017, the European project PowderReg promotes the development of a cross-border research pipeline of excellence in the field of rheology. Coordinated by the Université de Lorraine, it is funded by the European program Interreg VA Grande Région as part of priority axis 4 “Strengthening the competitiveness and attractiveness of the Grande Région.

This project consists of characterizing powders and granular media in industry to understand their behavior under different conditions. It aims to optimize the processes of implementation of powders by proposing innovative solutions to facilitate their supply, storage and treatment. Various types of powders with different properties are studied: food, chemical, pharmaceutical, building. For industries, a better understanding of the behavior of powder flows represents a major economic stake to avoid huge losses but also to develop their capacity of innovation in terms of production and transformation of products.

The consortium is made up of 5 universities of the Greater Region, experts in the field of powders and granular media. The LEMTA, LIBIO and LRGP laboratories of the Université de Lorraine contribute their know-how in powder characterization. Two industrial partners, Granutools and Novacarb, are also involved in the project.

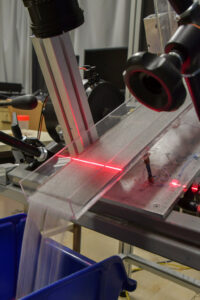

Using experimental and numerical tools, it is possible to characterize the movement of these materials. In this field, LEMTA researchers have a long experience and are working on the deployment of a new experimental device: a storage and shaping demonstrator. This tool has the ability to describe flows in order to predict, for example, possible blockages in silos. To remedy blockages in the material, the teams are looking to optimize the structure and design of the silos and add vibrations. The vibrations provide the necessary energy to the powders to fluidize their passage through the funnel and avoid blockages.

This project also focuses on the influence of environmental conditions such as humidity on the flow behavior of powders and their aging. The demonstrator is equipped with a climatic chamber that allows to vary the humidity rate up to 90%. This experimental study makes it possible to evaluate the sensitivity of powders to humidity and to make recommendations for their storage in optimal conditions.

Since its launch, this project has already resulted in 20 published articles and seven other articles in progress in international journals such as Powder Technology, Soft Matter or Europhysics Letters. These publications were written jointly with the project partners. The teams also participated in 9 international congresses and conferences during which they presented 35 oral communications and posters. Two doctoral students in the laboratory were recruited on this project to understand and determine the behavior of powders under different processing conditions.

PowderReg will be completed in December of this year. A closing meeting will allow a complete assessment of the work initiated during these 5 years.

For more information, you can visit the project website.

Left: Schematic of the storage demonstrator. Right: the storage demonstrator being finalized.