From hydrogen production to energy recovery

- Analysis and improvement of the performance and lifetime of electrochemical systems such as Polymer Membrane Fuel Cells (PEMFCs) and Water Electrolyzers (PEMWEs), Solid Alkaline (SAFCs) and Direct Borohydride Fuel Cells (DBFCs) and Redox Flow Batteries (RFBs)

- Electrochemical and physical (adsorption-desorption) hydrogen compression

- Electrical characterization of SuperCapacitors (SCs)

- Hydrogen production by water electrolysis

- Manufacture of electrodes for fuel cells by spray deposition

Specificities

- Scientific expertise in charge, heat and mass transfer phenomena as well as material ageing conditions

- Fine and real time instrumentation of cells – segmented cells

- Development of test benches

- Development of innovative architectures

Application sectors

- Transportation

- Stationary and electro-portable equipment

Keywords

- Hydrogen

- Electrochemical converters

- Fuel cells (PEMFC, SAFC, DBFC), water electrolyzer (PEMWE), redox flow batteries, supercapacitors, Hydrogen electrochemical compression/purification

- Instrumented and segmented cells

- In-situ and ex-situ characterization

- Performance

- Aging/degradation

- Realization of instrumented and segmented electrochemical cells allowing the local and in-situ application of most electrochemical tools: polarization curves, Electrochemical Impedance Spectroscopy (EIS), Cyclic Voltammetry (CV), measurement of ElectroChemical Active Surfaces (ECSA), electrode potentials, ionic resistances, hydrogen permeation, temperatures, pressures, etc.

- Development of models for the fine analysis of experimental data and the identification of characteristic parameters

- Analysis of degradation phenomena and development of mitigation strategies

- Electrode manufacture : standard, innovative reduced or platinum-free electrodes

- Manufacture of Membrane-Electrode Assemblies (MEAs)

- Membrane characterization : water and ion transport parameters, aging

- Innovative cell and stack architectures for PEMFCs and PEMFC-SC hybridization

- 10 multi-instrument and piloted test benches for low-power single cells (segmented or not) installed in 4 air-conditioned and secure experimentation boxes allowing experiments to be carried out 7 days a week, 24 hours a day

- 1 high pressure hydrogen compressor bench by adsorption-desorption up to 700 bars

- Devices for the manufacture of MEAs (by spray deposition for electrode manufacturing, laser cutting, heating press)

Thermistack maturation project supported by SATT Grand Est (Sayens)

The Thermistack maturation project (2018-2019) aimed at valorizing a LEMTA patent (WO/2014/060198. 2014) to develop a 5 kW PEMFC stack prototype according to an innovative architecture allowing to limit degradation by a differentiated thermal control of the anodes and cathodes. This architecture could meet stationary energy production needs (e.g. small collective BBC building).

Thermistack single cell

Prototype of hydrogen compressor per adsorption-desorption cycling

Compression system without any moving mechanical element, capable of carrying hydrogen up to 700 bar per adsorption-desorption cycle on activated carbons with very high specific surface area. Doctoral study by Giuseppe Sdanghi carried out within the framework of the LUE Impact ULHyS project.

Prototype of hydrogen compressor by adsorption-desorption

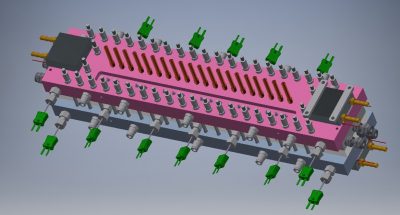

Segmented fuel cell developped in collaboration with Bosch

In the framework of the LUE Impact ULHyS project, two doctoral studies started in 2019 in collaboration between Bosch – Stuttgart and LEMTA. Experimental evaluation and validation of mass transport models will be confronted for PEMFCS for transport application.

CAD view of the multi-instrumented segmented cell

Jérôme Dillet

Jerome.dillet@univ-lorraine.fr

+33 (0)3 72 74 42 37

LEMTA

2 avenue de la Forêt de Haye

BP 90161

54505 VANDOEUVRE-LÈS-NANCY CEDEX