Solid rheology of polymers and composites

Platform dedicated to the study of polymer and composite thermo-mechanical properties

We have a multi-purpose experimental park dedicated to the study of polymer and composite properties :

- Dynamic Mechanical Analysis (DMA) in tensile, compression, bending or shear (on film) modes

- Multi-axial tests (tensile-torsion)

- Temperature tensile or bending tests

- Fatigue properties

- Relaxation and creep tests

Specificities

- The tests can be coupled with kinematic (displacements-strains) or thermal fields measurements obtained on the specimen surface

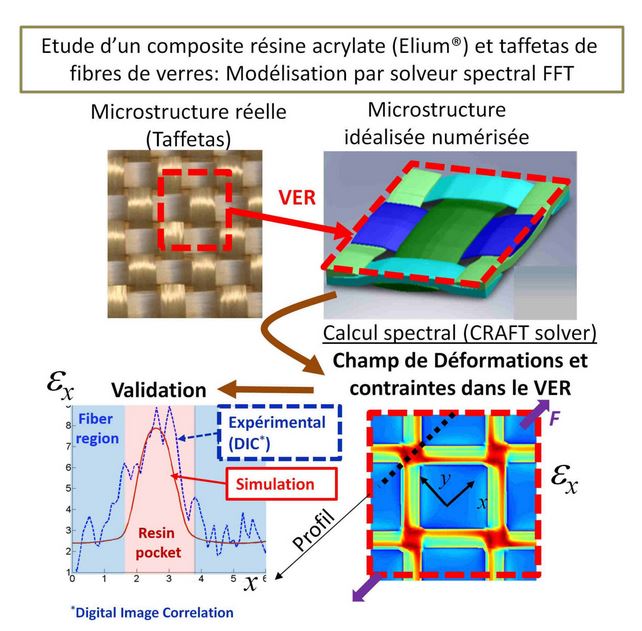

- The experimental results can be associated with modelling of material mechanical behaviours obtained with Finite Element (Abaqus, FlexPDE), spectral (Craft) or « phase field » codes

Application sectors

- Polymer thermo-mechanical properties

- Composite mechanical properties, study of damage development in composites

- Experimental determination of polymer and composite behaviour laws

Keywords

- Polymers

- Composites

- Thermo-mechanical testing

Thermo-mechanical characterization of polymers and composites

- Measurements of polymer mechanical properties: True stress/True strain curves, Young’s modulus, Poissons’s ratio, creep threshold, strain and stress at break

- Measurements of composite mechanical properties: Elastic moduli, damage threshold, tensile and flexural strengths, ILSS (InterLaminar Shear Strength) and fatigue limit

- DMA measurements of conservative and loss moduli with temperature or frequency sweeps. Data analysis: determinations of glass transition and secondary relaxation temperatures

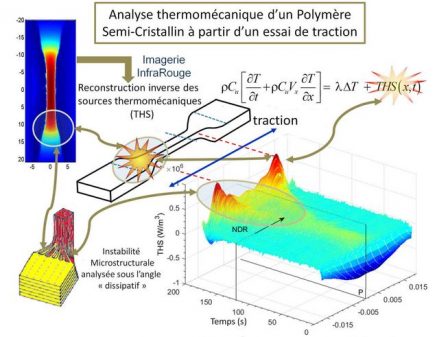

Exploitation of kinematic and thermal field measurements

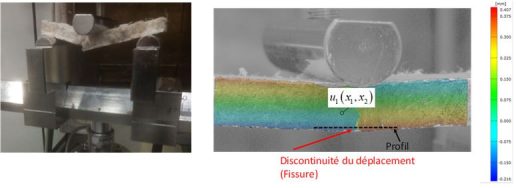

- 3D image correlation: strain localization (necking) in polymers deformed in tension, strain variations at the meso-scale for composite materials

- IR Camera: damage development in composites followed by heat dissipation measurements. This is an alternative to the long and tedious measurement of the Wöhler’s curves

- Hydraulic press MTS 100kN with a Flextest SE controller

- Tensile/torsion machine MTS Bionix 25kN with a Flextest 60 controller

- Tensile/fatigue machine Bose 3.3kN: Fatigue, DMA: 0.001-10 Hz, thermal chamber, 3 points bending bench.

- Dynamic Mechanical Analysis device Metravib DMA 300 ±150 N, 7 stiffness decades, tensile, bending and shear (on film) modes

- Mini-machine Kammrath&Weiss 5kN: Tensile or compression machine dedicated to in situ studies performed in a SEM (Scanning Electron Microscope) or with synchrotron radiation.

- ARAMIS (3D image correlation)

- RealTime VideoExtensometry (internal development)

- Incoherent Polarized Steady Light Transport technique (internal development)

- IR camera associated with homemade codes used to reconstruct the heat sources

Mechanical properties of an aerogel « wood composite » for thermal isolation purposes

Mechanical strength and damage mechanisms analysis for an aerogel « wood composite » using a 3-points flexural bench coupled with image correlation measurements. The analysis of the kinematic fields makes it possible to show that failure is due to the development of cracks in the beam areas subjected to tensile stresses.

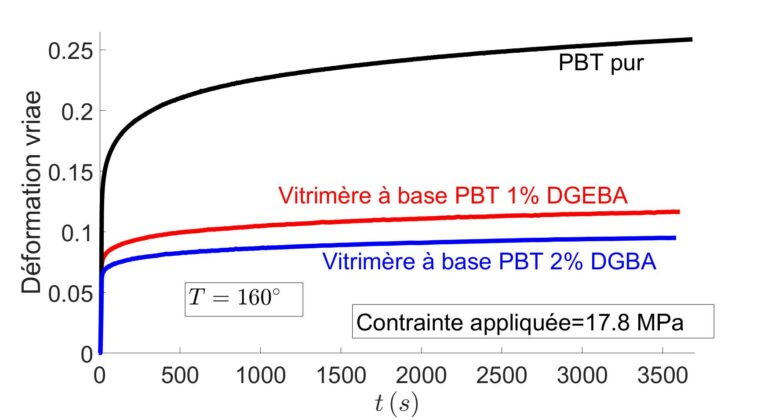

PBT based vitrimers: improvement of Creep properties

Temperature creep tests combined with image correlation measurements have shown that the « vitrimerization process » significantly improved the creep properties of PBT.

Stéphane André

stephane.andre@univ-lorraine.fr

+33 (0)3 72 74 42 96

Laurent Farge

laurent.farge@univ-lorraine.fr

+33 (0)3 72 74 42 82

LEMTA

2 avenue de la Forêt de Haye

BP 90161

54505 VANDOEUVRE-LES-NANCY CEDEX